The Project:

Fine-tune print parameters in Prusa Slicer to achieve the largest print by volume in under two hours. It must hold its shape, some errors are allowed but it still needs to look like a Ditto.

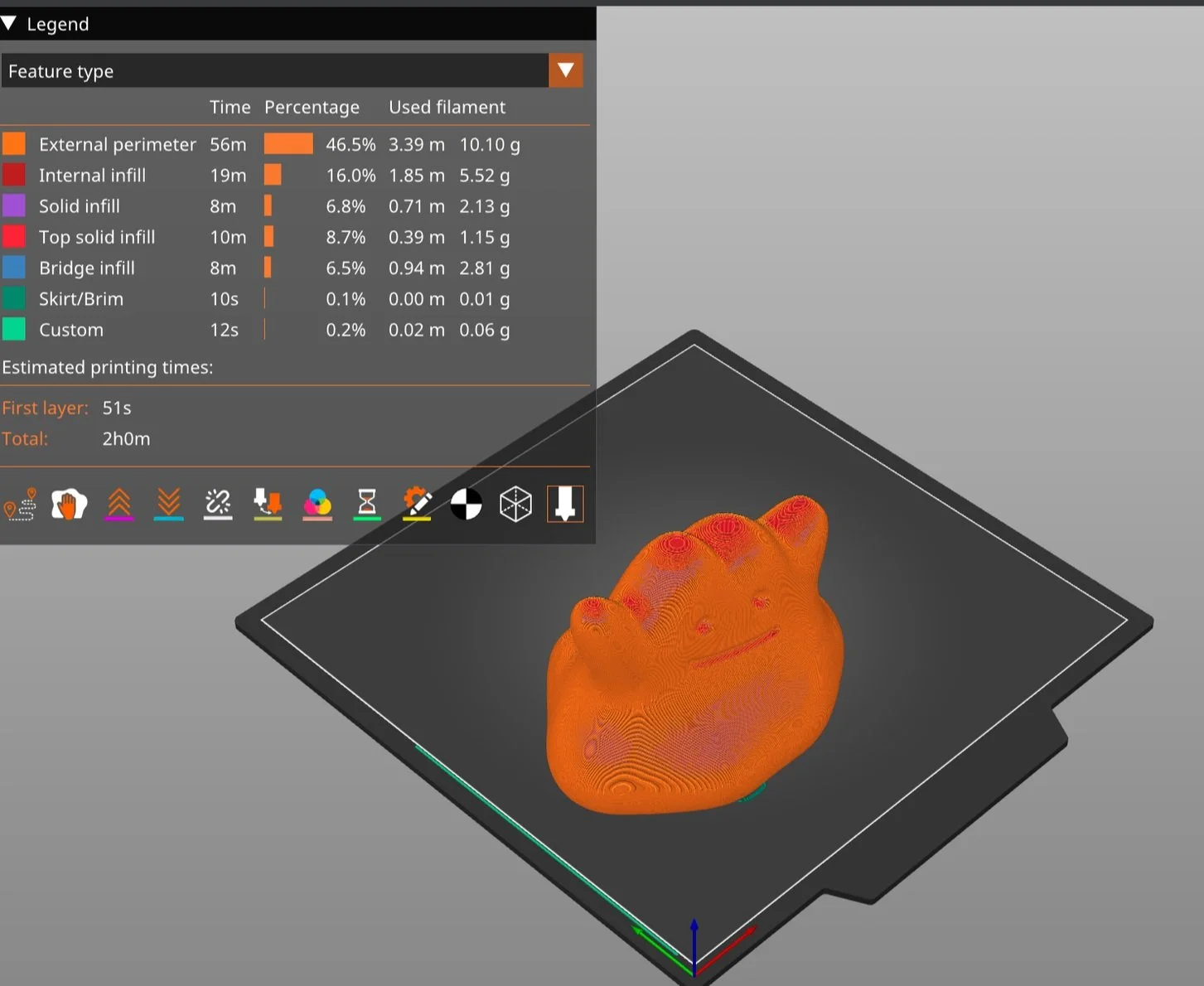

PrusaSlicer settings:

Layer Height (.28 mm → .3 mm):

Increasing the layer height reduces the number of layers needed for the same model height, leading to faster print times. However, this may slightly reduce the print's surface quality.Vertical Shells/Perimeters (3 → 1):

Reducing the perimeters from 3 to 1 decreases the number of outer walls, which significantly cuts down the print time.Horizontal Shells - Solid Layers (Top: 4 → 1, Bottom: 3 → 1):

Lowering the number of top and bottom solid layers greatly reduces the time spent on these dense areas.Ensure Vertical Shell Thickness (Enabled → Partial):

Changing from fully enabled to partial reduces the amount of compensation for vertical shell thickness, potentially decreasing material usage and print time.Seam Position (Nearest → Rear):

Setting the seam to the rear may slightly increase travel time because the printer will move to a specific area instead of selecting the closest path. However, the impact on print time is minimal compared to structural changes. I moved it to the rear so that it could have maybe a little more structural integrity with one seam.Seam Gap Distance (15% → 20%):

Increasing the seam gap distance reduces the frequency of retractions and seam starts, leading to smoother transitions and slightly faster prints.Fill Density (15% → 2%):

Reducing infill density significantly decreases print time because less material is deposited inside the model. This greatly affects the model’s internal strength.Fill Pattern (Grid → Support Cubic):

Switching to a support cubic infill pattern can be faster because it is optimized for support structures rather than dense fills.Maximum Length of the Infill Anchor (50 mm → 10 mm):

Reducing the anchor length decreases the distance the extruder travels for anchoring infill lines. This minimizes unnecessary movements, speeding up the print slightly.

II also adjusted the dimensions of the Ditto, making it shorter and wider because I was concerned the new settings would make it fragile, and a wider shape would provide more stability than a taller one.

Final Volume: 419,683.91 mm^3

Original Prusa Slicer Settings: 0.28 mm SUPERDRAFT SPEED (0.4 mm nozzle)

Time: 6 hours

Edited Prusa Slicer Settings

Time: 2 hours

Final Thoughts:

After changing the PrusaSlicer settings, the print time dropped from 6 hours to just 2, but at the cost of quality and strength. Reducing perimeters and solid layers caused visible holes and weak spots, while lowering infill density from 15% to 2% made the print fragile. Increasing the layer height to 0.3 mm resulted in rougher surfaces with less detail, and seam adjustments caused noticeable imperfections. While these changes improved speed, they significantly compromised durability and appearance, making them better for quick prototypes than functional parts.